Iron powder toroidal cores pdf

Find great deals on eBay for Iron Powder Core in Electrical Inductors, Coils, and Filters. Shop with confidence.

Evaluation of competitor-produced equivalents of Micrometals powdered iron toroidal cores Hans Summers, January 2014 American-made Micrometals toroids are difficult to obtain and expensive to

26/12/2018 · Material: Carbonyl iron powder. 5xCarbonyl iron core. – High saturation magnetic flux density, able to work in a large current. – The annular structure has a very low electromagnetic radiation shielding. eBay!

MATERIAL #2 (µ=10): A Carbonyl ‘E’ iron powder material having high volume resistivity. Offers high ‘Q’ for the 2 MHz to 20 MHz frequency range. Available in toroidal form and shielded coil form. Offers high ‘Q’ for the 2 MHz to 20 MHz frequency range.

Micrometals iron powder toroidal cores are available in a very large selection of sizes and material types. In general, most of the Micrometals toroidal core tooling allow for doubling the

of Iron-Silicon powdered particles, compacted into geometries such as toroid, block, E or U-core shapes. The powder metal compaction process produces a product with excellent core loss

Iron powder cores are commonly used to produce high Q inductors and transformers for selective circuits. Iron powder cores used in RF applications are composed of extremely small

HOME APPLICATION NOTES Elna Magnetics

IRON POWDER CORES fericor.com

RF Iron (carbonyl) Powder cores Low Frequency Iron Powder coresLow Frequency Iron Powder cores DuraFlux High Energy cores . Page 2 MMG IOM Limited Table of Contents Section – Toroid Cores Core dimensions page 4 – 8 MPP & High Flux cores Low Frequency Iron and RF Iron (carbonyl) Powder cores DuraFlux High Energy cores Core AL values page 9 – 13

FUAN PAIRUI Iron Powder Cores KT-94-14 KT: Toroidal Cores. 94 : Core Size. 14 : Material. Dimension: (UNIT:mm) Tolerance includes coating OD 23.90 ± 0.75

CWS ByteMark : Iron Powder Toroidal Cores for RF Applications – Products Cross Reference Part Numbers Quote Request inductors, transformers, chokes, surface mount inductors, surface mount transformers, Surface Mount Filters, power transformers, common mode chokes, differential mode chokes, output chokes, ceramic chip inductors, wirewound chip

TOROIDAL CORES : IRON POWDER CORES. Iron Powder Cores are made in numerous shapes and sizes: such as Toroidal Cores, E- cores, Shielded Coil Forms, Sleeves etc., each of which is available in many different materials.

High Flux cores are distributed air gap toroidal cores made from a nickel-iron alloy powder. Containing 50% nickel, and with processing costs comparable with MPP, High …

Toroidal Cores 5 Iron Powder Cores are fitted for temperature range from -65! to +125! .When cores are placed in higher temperature over 150! , it will make

Note: Due to the nature of the ‘0’ material, the inductance resulting from the use of the given A L value may vary greatly depending upon the winding technique.

Iron powder cores are commonly used to produce high Q inductors and transformers for selective circuits. Iron powder cores used in RF applications are composed of extremely small particles of highly pure carbonyl iron. The distributed air-gap of iron powder cores contributes to their rather low permeability and very good stability. In applications involving low-level signals, the choice of

Iron Powder Materials Neosid high permeability iron powder cores are manufactured in two grades using selected types of iron powder. During manufacture the powder is insulated by controlled surface treatments prior to mixing with a bonding material and

iron powder toroid cores-xx Iron powder cores are more stable than ferrites and do not saturate as easily so they are best for tuned circuits, filters, and high power inductors. They come in different “Mixes” for use at different frequencies.

Iron Powder Cores: Calculating no. of turns (N), inductance values (L) and AL values. Iron Powder Materials : Description of RF material types with permeabilities of 1 to 75 Iron Powder Toroidal Cores : Table of RF Materials showing OD, ID, Ht, Le, Ae, Ve and AL of

Iron Powder Cores are made in numerous shapes and sizes: such as Toroidal Cores, E- cores, Shielded Coil Forms, Sleeves etc., each of which is available in many different materials.

Ferrite type cores will require fewer turns, will give more impedance per turn and will couple better, whereas the Iron Powder cores will require more turns, will give less impedance per turn, will not couple as well but will tolerate more power and are more stable.

A magnetic core is a piece of magnetic material with a high magnetic permeability used to confine and guide magnetic fields in electrical, electromechanical and magnetic devices such as electromagnets, transformers, electric motors, generators, inductors, magnetic recording heads, and …

Powder Cores are made from discrete particles of ferromagnetic powder. Prior to being formed into a core, the Prior to being formed into a core, the particles are covered in a thin layer of electrically insulated material to ensure electrical isolation of each

Amidon iron powder toroids are often used for high Q narrow-band tuned circuits in the specified frequency or for wide band not tuned circuits on a much larger bandwidth than specified. The AL value is equal to the inductance value for 100 turns winded on the ferrrite core.

Iron Powder Cores Micrometals are a world renowned manufacturer of Iron Powder Cores and Power Magnetics is proud to represent them as an authorised agent and distributor of their products. Micrometals Iron Powder Toroidal Cores have a distributed air gap and are available in material grades covering many applications.

Cores Used by Butler Winding: Powdered Iron Iron alloys are ground and thoroughly mixed with a binding material, then pressed in a press to form a core. The binding material is an insulator; hence it reduces the eddy currents.

0.002 to 0.000125 inches, then slit and wound into tape cores, such as C cores, E cores and toroids. The powder cores, such as powder molypermalloy and powdered iron materials, are die-pressed into toroids, EE cores and slugs.

5 pieces Micrometals Amidon T68-2 Iron Powder Toroidal Core T-68-2 Toroid ATAU Material: Carbonyl iron powder. 5xCarbonyl iron core. – The annular structure has a very low electromagnetic radiation shielding.

Shen Zhen toroid base with pins. PC base for toroid winding. 4 legs. Can use up to a T25 toroid. 7mm (0.270″) diameter well. PC base for toroid winding. 4 legs.

Iron Powder Cores are made in numerous and sizes: such as Toroidal Cores, E-cores, Shielded Coil Forms, Sleeves etc., each of which is available in many different materials.

Using Magnetic Cores at High Temperatures All cores are not the same. Designers need to know the differences in order to make the best choices. Thermal considerations are a basic part of power electronics design. Components can be heated by external sources, and they can be heated by their own energy losses. Inductors and transformers are often designed for significant temperature rise in

Genalex & Genalex H (nickel Genalex & Genalex H (nickel

Title: iron powder cores,B-H curves,transformers,micrometals cores,toroidal cores,HC cores,IC cores Author: Yuxiang Magnetic Material Ind Co.,Ltd.

roidal cores ar 15%. with ae n sep ated effects. r winding in order o minimize leak FACE COATING al iron powder cores, manufactured by this 3 well finished with protecting paint. The minimum rength of coating is 600Vrms under 50Hz. c strength also may be increased according to the Istomer. The surface of E—shaped and I—shaped eated with antirust material. We suggest the user to the

Infantron Singapore widely manufacture and distributes Micrometal Cores, Micro Metal Powder Core, Micrometal Toroid Core, Micrometal Power Cores.

amidon 43 toroid core datasheet, cross reference, circuit and application notes in pdf format. – instructions after flowerhorn lays eggs Amidon Tech Data. We’re currently updating this page. If you have any inquiries regarding our products and specifications, please contact us. Ferrite Material

BRIEF INTRODUCTION TO IRON POWDER CORES Iron Powder Cores are made in numerous shapes and sizes: such as Toroidal cores, E-cores, Shielded Coil

Title: toroids,toroidal cores,magnetic winding core,iron powder toroidal core,powdered cores,alpha-core Author: lvl Created Date: 6/12/2007 10:32:10 AM

ferrites, iron powder, Sendust, MPP and High flux cores. Nano crystalline materials will be mentioned but Nano crystalline materials will be mentioned but will not be put to the test due to their working conditionsbeing lower frequencyapplications.

magnetic powder cores. Today, we are well positioned to offer reliable product quality at competitive Today, we are well positioned to offer reliable product quality at competitive prices to meet the diverse requirements of all our clients.

turns on a toroidal core (only integer numbers allowed), we will be somewhat low in inductance with 3 turns: about 79 nH. The Iron Powder table indicates that a T-37-12 core has an A

In iron powder cores saturation flux densities of more than 1 T can be utilized, depending on the material. As you mentioned Micrometals core: Micrometals, Inc. offers an Inductor Design Software that can be used to design basic inductors including power loss calculations.

Part Number A L nH/N2 OD mm ID mm HT mm Le cm Ae cm2 V cm3 STANDARD SPECIFICATIONS Http://www.fuantronics.com Toroidal Cores IRON POWDER CORE SERIES PRODUCTS

www.mag-inc.com CONTENTS GENERAL INFORMATION 1-1 Introduction 1-2 Applications 1-3 Core Identification 1-4 General Powder Core Information CORE SELECTION

Iron powder cores do not need the additional air gap since it is integrated into the material and, in consequence, spread within the complete core volume. This reduces the eddy current losses in the winding and the remaining eddy current losses are distributed throughout the winding length.

The compaction process used to produce iron powder cores is suitable to make a wide variety of configurations. Toroidal cores, E-cores, U-cores, Slugs, and Bus-Bar cores are all available

Based on above features, iron powder core are widely used in power switching inductor, online noise filter, PFC inductor, choke EMI/RFI application and etc. The toroidal cores …

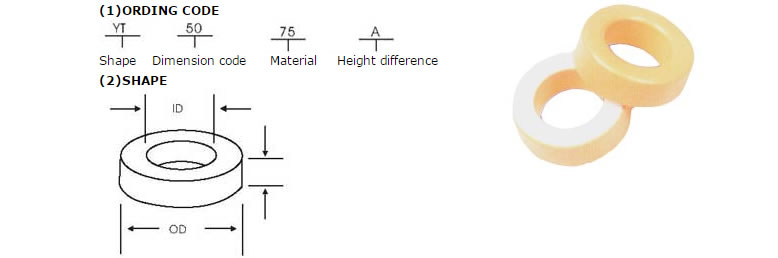

T = Toroidal Core 130 = Outer diameter dimension= 1.30 inch/33mm. 2 = Iron Powder Material Grade. (Red) O.D. – is the outer diameter of iron powder toroid core I.D. – is the inside diameter of iron powder toroid core Height – is the height or the thickness of iron powder toroid core Material Grade – is the Iron Dust material type. Applications in function of core material grade Materials: 2-4

Toroids Ferrite & Powder

Apart from the physical dimensions of a toroid (outside and inside diameter, thickness) there is a value given for each particular core size and material, which is usually called the AL value, and is the manufacturer’s inductance index for the core. Manufacturer’s data for iron powder and ferrite cores are in the data tables and show all the required information. The

Inductors: Ferrite and Powder Toroids. Molydenum toroid, ferrite toroid core, high flux, strip wound toroid, high voltage nylon coated ferrite toroid, the perfect toroid wire PTFE – 14AWG, stainless steel tape wound core.

Dongbu CNI Dongbu CNI Dongbu CNI Dongbu CNI DONGBU ELECTRONIC MATERIALS Dongbu CNI Dongbu CNI Dongbu CNI Dongbu CNI Innovation for a creating Customer value Innovation for a creating Customer value POWDER CORES MPP/High Flux/Sendust/Power Flux/Ultral Flux. Introduction Dongbu Electrinic Materials Co., Ltd. is a fine chemical product manufacturer jointly invested by …

Ferrite toroids Toroids are one of the most cost effective ferrite shapes available. Although the cost of winding on a toroidal core may be higher, the benefit of not having to be assembled and the excellent magnetic shielding offered are reasons that maketoroidal cores one of the most used geometries today.

Iron powder toroidal core is seldom necessary to shield a toroidal inductor as most of the flux lines are contained within the core. Features of toroidal cores The maximum operating temperature of toroidal cores is 150℃.

SMD CHIP BEAD / INDUCTOR EMI CORES NI-ZN

Iron Powder Toroidal Core Magnets By HSMAG

Toroids is a curation of 15 resources about , Toroids – Some practical considerations, Online Calculators for Radio & Electronic Design, Winding Toroids, LA6PB’s split dipole, Toroid Winding. Resources listed under Toroid category belongs to Components main collection, and get reviewed and rated by amateur radio operators.

IRON POWDER CORES SERIES PRODUCTS Le OD ID Ht Ae SYMBOL AND FORMULA CHARACTER OF IRON POWDER CORES: Toroidal iron powder cores, manufactured by this company, is well finished with protecting paint. The minimum dielectric strength of coating is 600Vrms under 50Hz. The dielectic strength also may be increased according to the needs of customer. The surface of E-shaped and I-shaped cores …

Iron powder is a cost-effective design alternative to alloy powder core materials. It can also can be used in place of ferrite and iron-alloy laminations requiring a gap. It can also can be used in place of ferrite and iron-alloy laminations requiring a gap.

IRON POWDER CORES 61 APPLICATIONS AND CHARACTERISTICS For design frequency below 300KHz, iron core is a prefered choice for RF CIRCIUTS, DC POWER SUPPLY CHOKES, MOTORS,

FTC-410 Toroid Core Standard UEI-310 U, E and I Core Standard YOUR ROLE Your comments on this User’s Guide and your suggestions on additional MMPA activities that would be helpful to your industry are welcome. Contact MMPA at: 8 South Michigan Avenue Suite 1000 Chicago, IL 60603 (312) 456-5590 Fax (312) 580-0165 E-mail: mmpa@ gss.net WebSite: www.mmpa.org If you prefer, please contact …

TOROIDAL CORES FIGURE : – 2 Red / Clear – 8 Yellow / Red – 18 Green / Red – 26 Yellow / White – 28 Gray / Green – 33 Gray / Yellow – 38 Gray / Black – 40 Green / Yellow

POWDER CORES Molypermalloy Kool Mµ®, XFlux®, power ferrites, high permeability ferrites and strip wound cores, Magnetics’ products set the standard for providing consistent and reliable electrical properties for a comprehensive range of core materials and geometries. Magnetics is the best choice for a variety of applications ranging from simple chokes and transformers used in

Toroidal inductors and transformers are inductors and transformers which use magnetic cores with a toroidal (ring or donut) shape. They are passive electronic components, consisting of a circular ring or donut shaped magnetic core of ferromagnetic material such as laminated iron, iron powder, or ferrite, around which wire is wound.

Using Magnetic Cores at High Temperatures

Micrometals Powder Core Solutions

The insulated powder is then compacted into EE and toroidal cores. The toroidal cores range in size from The toroidal cores range in size from 0.25 inch (0.635 cm) to …

High Temperature Iron Powder Toroidal Chokes APPLICATION FEATURES The PL Series Chokes are offered for use in high-frequency power-supply applications at a lower cost than nickel powder cores.

B-H CURVES OF THE IRON POWDER CORES Magnet-tech

Iron Powder Toroidal Cores for RF Applications CWS

toroidstoroidal coresmagnetic winding coreiron powder

human physiology silverthorn pdf reddit – Toroids Micro Metals / Iron Powder – Surplus Sales of

IRON POWDER CORE SERIES PRODUCTS Toroidal Cores

PAIRUI Iron Powder Cores KT-94-2 fuantronics.net

Inductor Construction UC Santa Barbara

IRON POWDER CORE SERIES PRODUCTS Toroidal Cores

toroidstoroidal coresmagnetic winding coreiron powder

Amidon iron powder toroids are often used for high Q narrow-band tuned circuits in the specified frequency or for wide band not tuned circuits on a much larger bandwidth than specified. The AL value is equal to the inductance value for 100 turns winded on the ferrrite core.

Toroidal Cores 5 Iron Powder Cores are fitted for temperature range from -65! to 125! .When cores are placed in higher temperature over 150! , it will make

IRON POWDER CORES 61 APPLICATIONS AND CHARACTERISTICS For design frequency below 300KHz, iron core is a prefered choice for RF CIRCIUTS, DC POWER SUPPLY CHOKES, MOTORS,

Cores Used by Butler Winding: Powdered Iron Iron alloys are ground and thoroughly mixed with a binding material, then pressed in a press to form a core. The binding material is an insulator; hence it reduces the eddy currents.

Title: iron powder cores,B-H curves,transformers,micrometals cores,toroidal cores,HC cores,IC cores Author: Yuxiang Magnetic Material Ind Co.,Ltd.

26/12/2018 · Material: Carbonyl iron powder. 5xCarbonyl iron core. – High saturation magnetic flux density, able to work in a large current. – The annular structure has a very low electromagnetic radiation shielding. eBay!

Using Magnetic Cores at High Temperatures All cores are not the same. Designers need to know the differences in order to make the best choices. Thermal considerations are a basic part of power electronics design. Components can be heated by external sources, and they can be heated by their own energy losses. Inductors and transformers are often designed for significant temperature rise in

FTC-410 Toroid Core Standard UEI-310 U, E and I Core Standard YOUR ROLE Your comments on this User’s Guide and your suggestions on additional MMPA activities that would be helpful to your industry are welcome. Contact MMPA at: 8 South Michigan Avenue Suite 1000 Chicago, IL 60603 (312) 456-5590 Fax (312) 580-0165 E-mail: mmpa@ gss.net WebSite: www.mmpa.org If you prefer, please contact …

iron powder toroid cores-xx Iron powder cores are more stable than ferrites and do not saturate as easily so they are best for tuned circuits, filters, and high power inductors. They come in different “Mixes” for use at different frequencies.

www.mag-inc.com CONTENTS GENERAL INFORMATION 1-1 Introduction 1-2 Applications 1-3 Core Identification 1-4 General Powder Core Information CORE SELECTION

Based on above features, iron powder core are widely used in power switching inductor, online noise filter, PFC inductor, choke EMI/RFI application and etc. The toroidal cores …

Permeability 35 35 6.0 25 55 75 22 22 33 33 33 85 60 I emp

Iron Powder Cores Palomar Engineers®

Evaluation of competitor-produced equivalents of

Iron powder cores are commonly used to produce high Q inductors and transformers for selective circuits. Iron powder cores used in RF applications are composed of extremely small

Iron Powder Toroidal Cores for RF Applications CWS

Ferrite toroids Neosid

BRIEF INTRODUCTION TO IRON POWDER CORES Iron Powder Cores are made in numerous shapes and sizes: such as Toroidal cores, E-cores, Shielded Coil

Evaluation of competitor-produced equivalents of

Iron/Magnetic/Ferrite Micrometals Powder Cores Infantron

Micrometals Iron Powder Cores Magnetics

Title: iron powder cores,B-H curves,transformers,micrometals cores,toroidal cores,HC cores,IC cores Author: Yuxiang Magnetic Material Ind Co.,Ltd.

Iron Powder Cores cdn-reichelt.de

Evaluation of competitor-produced equivalents of Micrometals powdered iron toroidal cores Hans Summers, January 2014 American-made Micrometals toroids are difficult to obtain and expensive to

Toroidal inductors and transformers Wikipedia

Iron Powder Core Passive Components eBay

Iron Powder Materials Neosid high permeability iron powder cores are manufactured in two grades using selected types of iron powder. During manufacture the powder is insulated by controlled surface treatments prior to mixing with a bonding material and

POWDER CORES Magnetics

Construction tips for using iron powder cores