Old Craftsman air compressor manuals are essential for understanding and maintaining vintage models. They provide detailed operation, maintenance, and troubleshooting guides, while also offering historical insights into compressor technology evolution.

1.1 Overview of Craftsman Air Compressors

Craftsman air compressors are trusted tools for various applications, ranging from small workshops to industrial settings. Known for their durability and reliability, these compressors come in different models, including oil-lubricated and oil-free designs. They are designed to deliver consistent air pressure for powering tools and equipment. Over the years, Craftsman has evolved its technology to meet changing demands while maintaining high performance standards.

1.2 Importance of Manuals for Proper Operation

Craftsman air compressor manuals are crucial for safe and efficient operation. They provide detailed instructions for setup, maintenance, and troubleshooting, ensuring users understand their equipment’s capabilities and limitations. Adhering to the manual’s guidelines helps prevent accidents, optimizes performance, and extends the compressor’s lifespan. It serves as a comprehensive reference for both novice and experienced operators.

Where to Find Old Craftsman Air Compressor Manuals

Old Craftsman air compressor manuals can be found on Sears’ official website, third-party archives like Manualzilla, and vintage marketplaces such as eBay and specialized forums.

2.1 Official Sears and Craftsman Websites

The official Sears and Craftsman websites provide a comprehensive repository of old air compressor manuals. Users can search by model number or product category to find and download PDF versions of manuals, ensuring authenticity and reliability. These resources are regularly updated and offer a user-friendly interface for easy access to necessary documentation.

2.2 Third-Party Manual Archives

Third-party websites like Manualzilla and ManualsLib offer extensive collections of old Craftsman air compressor manuals. These platforms aggregate and host PDF versions of manuals, making them accessible for free download. They often include a wide range of models, ensuring that even rare or discontinued manuals are available for users seeking repair or maintenance guidance.

2.3 Vintage or Used Marketplaces

Vintage or used marketplaces like eBay, Etsy, and specialized forums often host old Craftsman air compressor manuals. These platforms allow users to purchase rare or discontinued manuals, often in digital or physical formats. Collectors and enthusiasts frequently list these items, making them valuable resources for those seeking hard-to-find documentation for vintage models.

Key Components of Old Craftsman Air Compressor Manuals

Old Craftsman air compressor manuals include detailed specifications, safety guidelines, assembly steps, maintenance schedules, and troubleshooting tips, ensuring comprehensive guidance for optimal performance and longevity.

3.1 Specifications and Technical Details

Old Craftsman air compressor manuals detail essential specifications, such as horsepower, PSI, and tank capacity, providing a clear understanding of the unit’s capabilities and operational limits. These technical details are crucial for proper setup, maintenance, and ensuring safe, efficient performance, helping users optimize their equipment for various tasks and tools.

3.2 Safety Rules and Precautions

Old Craftsman air compressor manuals emphasize critical safety rules, such as operating on a dedicated 15-amp circuit, avoiding extension cords, and ensuring proper ventilation. They highlight potential hazards like overpressure and electrical risks, providing clear guidelines to prevent accidents and ensure safe, efficient operation of the equipment.

3;3 Assembly and Installation Instructions

Old Craftsman air compressor manuals provide detailed assembly and installation guidance, ensuring proper setup and functionality. They include step-by-step instructions for unpacking, locating components, and connecting parts. Specific models, like the 921.153100, outline procedures for mounting and aligning the compressor. These manuals also emphasize the importance of following instructions to avoid errors and ensure safe, efficient operation of the unit.

3.4 Maintenance and Troubleshooting Guides

Old Craftsman air compressor manuals include comprehensive maintenance schedules and troubleshooting tips. They cover oil lubrication, filter replacement, and belt adjustments to ensure optimal performance. Troubleshooting sections address common issues like tripping breakers or low air pressure, providing step-by-step solutions and part replacement guidance for models such as the 921.153100, helping users maintain and repair their compressors effectively.

Understanding the Operation of Old Craftsman Air Compressors

Old Craftsman air compressors operate by using an electric motor to drive the pump, compressing air into a storage tank. The pressure switch regulates operation, turning the motor on and off based on set pressure levels. Manuals detail these principles, ensuring safe and efficient use of vintage models like the 921.153100.

4.1 Basic Principles of Air Compression

Air compression involves converting electrical energy into pressurized air. The motor powers a pump, drawing in air and compressing it into a tank. As pressure rises, a switch deactivates the motor. Old manuals, like the Craftsman 921.153100, explain these cycles, ensuring users understand how their compressors function efficiently and safely, maintaining performance over time with proper care.

4.2 Control Panels and Adjustments

Control panels on old Craftsman air compressors feature pressure switches, gauges, and regulators. These components allow users to monitor and adjust output pressure, ensuring optimal performance. Manuals like the Craftsman 921.153100 model detail how to set cut-in and cut-out pressures, adjusting the pressure switch, and regulating airflow for specific tools, ensuring efficient and safe operation tailored to user needs.

Maintenance Tips for Vintage Craftsman Air Compressors

Regular oil changes, air filter replacements, and inspections of belts and hoses are crucial for maintaining vintage Craftsman air compressors, ensuring reliability and optimal performance over time.

5.1 Oil Lubrication and Filter Replacement

Regular oil lubrication is vital for maintaining vintage Craftsman air compressors. Check oil levels frequently and replace filters every 100 hours of use. Use high-quality oil suitable for air compressors to prevent overheating and wear. Replace the air filter by prying out the old one with pliers and installing a new one to ensure efficient operation and longevity.

5.2 Checking and Replacing Worn Parts

Regularly inspect belts, hoses, and gaskets for signs of wear. Replace worn or cracked components promptly to prevent leaks and maintain performance. Consult the manual for specific guidance on part replacement and compatibility. Timely maintenance ensures optimal functionality and extends the lifespan of your vintage Craftsman air compressor.

Troubleshooting Common Issues in Old Models

Address common issues like breakers tripping or low pressure by checking power supply, cleaning filters, and inspecting hoses for leaks, ensuring optimal compressor performance.

6.1 Why Compressors Trip Breakers or Overheat

Old Craftsman compressors may trip breakers due to overloaded circuits, faulty capacitors, or motor issues. Overheating often results from clogged air filters, low oil levels, or excessive duty cycles. Regular maintenance, such as cleaning filters and checking oil, can prevent these issues and ensure reliable operation.

6.2 Solving Low Air Pressure Problems

Low air pressure in old Craftsman compressors can be resolved by inspecting for air leaks, cleaning or replacing the air filter, and ensuring proper pressure switch function. Additionally, checking the unloader valve, intake valve, and belt tension can help restore optimal performance. Regular maintenance, such as oil lubrication, also plays a crucial role in maintaining pressure stability.

Safety Guidelines for Using Vintage Air Compressors

Adhering to safety guidelines ensures safe operation of vintage air compressors. Always follow electrical setup recommendations and proper handling practices to minimize risks and maintain equipment longevity effectively.

7.1 Proper Electrical Setup and Usage

Ensure your vintage air compressor is connected to a dedicated 15-amp circuit to prevent overload. Avoid using extension cords unless necessary, and always check for sufficient free amps. Proper electrical setup is crucial for safe operation, as outlined in manuals like the Craftsman 921.153100 model, which specifies 125 PSI capacity. Adhere to all safety guidelines and manual instructions for optimal performance and risk reduction.

7.2 Handling and Storage Recommendations

Always handle vintage air compressors with care to avoid damage. Store them in a clean, dry environment, away from direct sunlight. For oil-lubricated models, ensure the unit is upright to prevent oil leakage. Regularly clean the compressor and drain moisture from the tank to avoid rust. Proper storage and handling extend the lifespan and maintain efficiency of your old Craftsman air compressor.

Compatibility of Old Manuals with Modern Units

Old Craftsman manuals may not fully align with modern units due to advancements in technology and design. However, basic principles and safety guidelines remain relevant for operation and maintenance.

8.1 Differences in Design and Technology

Old Craftsman air compressor manuals reveal outdated designs, such as oil-lubricated pumps, contrasting with modern oil-free models. Technological advancements like improved cooling systems and digital pressure switches enhance performance and efficiency. Compatibility issues arise due to differing components and controls. Users must adapt old manuals to contemporary units while maintaining reliability and extending equipment lifespan.

8.2 Adapting Old Manuals for Current Models

Adapting old Craftsman air compressor manuals for current models requires understanding both legacy and modern technologies. Update lubrication methods from oil-based to oil-free systems. Adjust control settings to match new digital interfaces. Ensure compatibility by referencing parts diagrams and updated safety standards for optimal performance.

DIY Projects and Modifications Using Old Manuals

Old Craftsman air compressor manuals inspire creative DIY projects, such as restoring vintage units or customizing compressors for specific tasks. They provide step-by-step guides for modifications, enabling users to breathe new life into classic equipment while maintaining its original charm and functionality.

9.1 Upgrading or Restoring Vintage Compressors

Upgrading or restoring vintage Craftsman air compressors involves replacing worn parts, lubricating components, and ensuring proper electrical setup. Old manuals guide users through disassembly, inspection, and reassembly, while also providing tips for maintaining original functionality. DIY enthusiasts can breathe new life into classic compressors, preserving their historical value while enhancing performance for modern use.

9.2 Customizing for Specific Tasks or Tools

Old Craftsman air compressor manuals often include tips for customizing units to suit specific tasks or tools. Users can modify settings, add accessories, or adjust components to optimize performance for particular applications. These guides help enthusiasts tailor their compressors for better efficiency, whether for woodworking, automotive work, or other specialized uses, enhancing versatility and functionality.

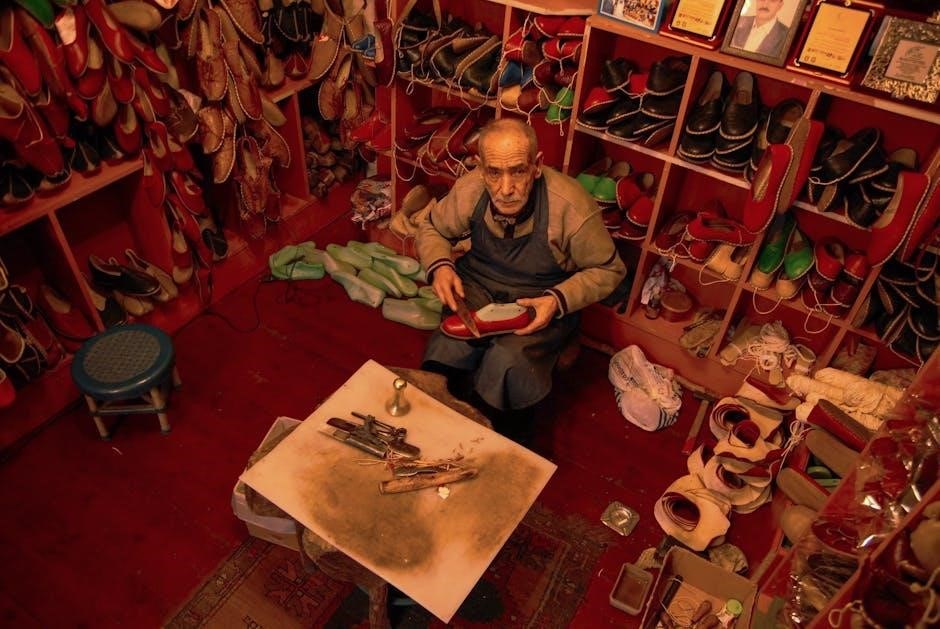

Historical Value of Vintage Craftsman Manuals

Vintage Craftsman manuals offer a historical record of air compressor development, showcasing technological advancements and design evolution over decades, making them valuable for collectors and historians alike.

10.1 Collectibility and Rarity

Vintage Craftsman air compressor manuals have become sought-after collectibles, especially for rare or discontinued models. Their rarity and historical significance make them valuable among enthusiasts and collectors of vintage tools, with some manuals fetching premium prices in specialized marketplaces and auctions due to their limited availability and nostalgic appeal.

10.2 Insights into the Evolution of Air Compressors

Old Craftsman air compressor manuals reveal the technological advancements in compressor design, from oil-lubricated to oil-free pumps. They showcase improvements in efficiency, safety, and durability, offering a historical perspective on how air compressors transitioned from bulky, industrial tools to compact, user-friendly devices for both professional and home use over the decades.